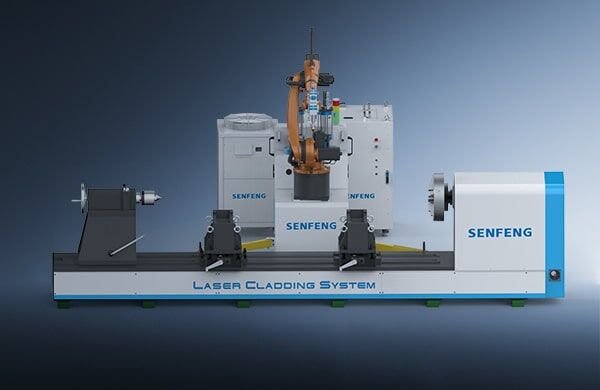

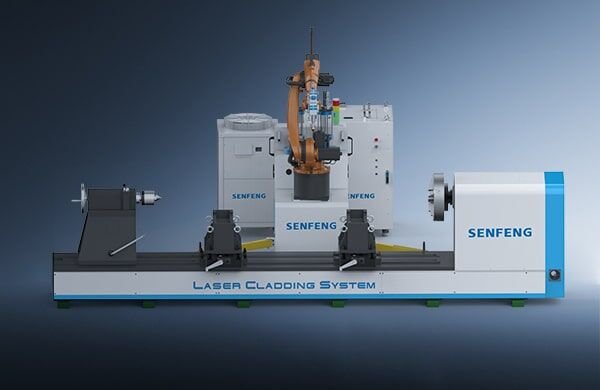

Mobile Robot Laser Cladding Machine SFMR02

This is a laser cladding machine based on 6-axis robot. Considering that the robot fills in for workers, the machine is highly optimized for general use at high degree of automation. It is easy for this multi-purpose model to clad workpieces with both simple and complex-shaped surface. In addition, the small-sized machine is easy to move and transported to customer’s site for cladding.

6 [kW] Laser power

20 [kg] Robot load (optional)

20-300 [μm] Powder size

150 [g/min] Max power feeding speed

Competitive Strengths

Performance Benefits

This flexible laser remanufacturing machine, self-developed based on 6-axis industrial robot, is easy to operate and has multiple functions. Now, it has got FDA, RoHS and CE certifications.

1. Good cladding ability

* Able to clad workpieces with planar, axial, curved, spherical and other special-shaped surfaces

* Accept self-fluxing alloyed, ceramic, composite powder and other metal metal wires

* Make workpiece surface much harder and more resistant to abrasion, corrosion, oxidation and high temperature, of which service life will be prolonged for 5-8 times than before

2. Automatic robot-assisted cladding

The 6-axis linkage robot, driven by AC servo motor, has 1813mm moving radius, 2000mm/s max moving speed and 20kg max load. That makes laser cladding automatic and easier.

3. Various cladding crafts

Our self-developed high-speed laser cladding head is compatible with annular, four-way, three-way or paraxial power feeding nozzle to offer high-speed, coaxial powder-fed, paraxial powder-fed and other laser cladding crafts. That is why users tend to get more choices.

4. Less manual intervention

Due to its high degree of automation, operating risks and costs will be lowered to make cladding safer and more flexible

5. Green and eco-friendly

Laser cladding usually results in no pollution nor radiation to environment, in accord with modern industry’s requirements

Mechanical Benefits

1. Deft design

* The highly integrated machine covers a small area for easy movement. Therefore, on-site cladding is made possible

* The robot is equipped with a mobile trolley on which there is lifting bracket used to keep the robot stable at work, so as to make sure of cladding precision

2. Self-developed laser generator

Unlike others, it has higher electro-optical conversion rate, lower power dissipation and better laser beam

3. Multi-purpose laser cladding head

It’s annular cladding nozzle and powder separator offer high-quality cladding together with multi-layer protective lens that can prevent smoke dust, spatter and water

4. Dual-cylinder pneumatic powder feeder

It is driven by smart control system and servo motor, just for stable powder feeding. With double transparent powder cylinders and powder mixing, you can visually observe powder residue, mix powders and avoid possible blockage.

5. Exclusive voltage stabilizer

It provides over-voltage, open-phase, phase sequence and mechanical failure protection. While withstanding transient overload, the stabilizer is free from waveform distortion, and keeps voltage adjustment more stable

Control System Benefits

SENFENG intelligent cladding system can take integrated control of the entire cladding process, such as centralized data treatment, fast response and high degree of automation. That will notably enhance cladding efficiency and precision.

1. User-friendly operation

The interface is easy to operate. That is, human-machine interaction, laser generator and powder feeding can be totally controlled on the CNC system interface.

2. Adjust parameters in real time

Laser power and powder feeding speed are adjusted in real time. In other words, you can change cladding parameters at work, with no need for shutdown.

3. Failure diagnosis

It may detect and output signal feedback in real time. In the event of a failure, automatic alarm will be given in time.

Get In touch

Technical Parameters

| Main Parameters | Model |

| SFMR02 | |

| Laser Power (kW) | 6 |

| Max Load of Robot (kg) | 20 |

| Coverage Area of Robot (mm) | 1813 (vary from different brands) |

| Laser Spot Size (mm) | φ2-φ5 |

| Fiber Core Diameter (μm) | 600 |

| Number of Powder Feeder Cylinders | 2 |

| Volume of Single Cylinder (L) | 2.5 |

| Powder Size (μm) | 20-300 |

| Max Powder Feeding Speed (g/min) | 150 |

| Powder Feeding Error | ≤1% |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) |

Get In touch

- Fully-covered protective sheet metals

Users are allowed to tailor protective sheet metals outfitted with remote start/stop button and monitoring modules to show actual running state of the machine

- Dual-axis positioner

Help users to get the optimal cladding position and speed particularly for large or heavy workpieces

- Offline software

Offline programming available to help out with the programming of special-shaped workpieces

- Inner-hole cladding head

Clad inner hole with min diameter of φ60mm

Get In touch

What is laser cladding and how does it work?

Laser cladding is an important method for surface modification of materials. It uses high-energy laser beam to irradiate the metal surface for rapidly melting, expanding and solidifying. The cooling rate typically reaches 102 to 106℃/s, then, a layer of material with special physical, chemical or mechanical properties will take its shape on the substrate surface, thus creating a new composite material. This process can compensate for the lack of high performance in the base material and significantly improve substrate surface properties in terms of wear, corrosion, high temperature and oxidation resistance.

What are technical characteristics of laser cladding?

Compared to commonly used methods such as overlay welding, thermal spraying and plasma spraying, laser cladding has the following advantages:

* The heat-affected zone is small, resulting in minimal deformation of workpiece and a high yield of cladding.

* The layer has fine crystal grains and dense structure, leading to relatively high hardness and better wear and corrosion resistance.

* Due to short duration of laser action, the dilution rate of cladding layer is low, which causes a smaller amount of material melted (typically 5%-8%). Therefore, it is possible to achieve the desired composition and properties even with a thin cladding layer, and to produce new structural features such as metastable phase, ultra-dispersed phase and amorphous phase.

* It is easy to automate the laser cladding, and the quality of cladding layer is always stable.

What materials are typically used for laser cladding?

The materials used for laser cladding are mainly thermal spraying and thermal welding materials, such as self-fusing alloy materials, carbide dispersion, or composite ceramic materials, which possess excellent wear and corrosion resistance. They are usually used in powder form, and during cladding, flames spray-welding may be employed to achieve a smooth surface with good adhesion to the substrate.

What is the warranty period of laser cladding machine?

The complete machine is under 1-year warranty. Its main accessories and consumables will be replaced depending on their specific service life. We also provide original accessories for global users, with quotes available within 24h and delivery within 3-7 working days. The change of these accessories will be given priority to our nearby subsidiaries or local service centers.