In the fast-paced world of metal fabrication, precision, speed, and efficiency are everything. Traditional cutting methods—such as mechanical shearing, plasma, or CO₂ lasers—have served the industry for decades. But today, fiber laser cutting has taken the spotlight, rapidly transforming how metal components are produced. At the forefront of this evolution is Gecnclaser, a global leader in fiber laser technology.

🔍 What is Fiber Laser Cutting?

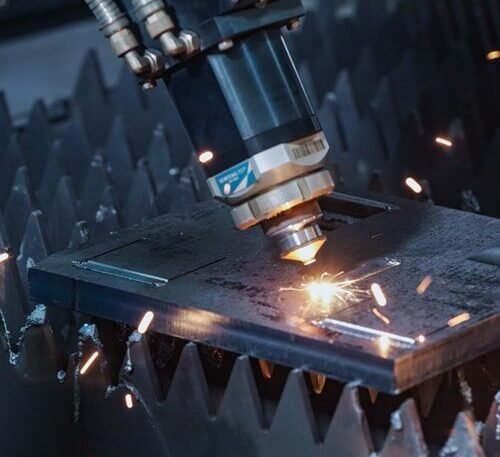

Fiber laser cutting is a process that uses a high-powered, focused laser beam transmitted through optical fiber to cut through metal materials with extreme precision. The laser source is solid-state, offering advantages over conventional CO₂ systems in terms of speed, energy efficiency, and maintenance.

⚙️ Key Benefits That Are Redefining the Industry

1. Unmatched Precision and Quality

Fiber lasers produce a much finer, cleaner cut than older technologies. With minimal heat-affected zones (HAZ), the edges are smoother, reducing the need for secondary processing like grinding or polishing.

✅ Ideal for intricate patterns and tight tolerances.

2. Faster Cutting Speeds

Compared to CO₂ lasers and other traditional methods, fiber lasers can cut up to 3x faster—especially on thinner materials. This translates directly to higher throughput and shorter lead times.

✅ Perfect for high-volume manufacturing environments.

3. Wider Material Compatibility

Fiber lasers can cut a wide range of metals, including:

Stainless steel

Carbon steel

Aluminum

Brass

Copper

This versatility makes it a go-to solution for industries like automotive, aerospace, construction, and electronics.

4. Lower Operating Costs

With no mirrors, less power consumption, and fewer maintenance requirements, fiber lasers are far more cost-effective in the long run. Gecnclaser’s advanced systems also integrate energy-saving features and automation to further optimize operational costs.

5. Automation-Friendly

Modern fabrication is moving toward smart factories and Industry 4.0. Fiber laser cutting machines—especially from Gecnclaser—are built to integrate with automation systems, robotics, and AI-powered monitoring tools for seamless, hands-free production.

🏭 How Gecnclaser is Leading the Change

At Gecnclaser, we have developed a full range of fiber laser cutting machines designed to meet the diverse needs of the fabrication industry. From compact systems for small workshops to large-scale machines for industrial production, our solutions are:

Engineered for durability and performance

Equipped with smart software for real-time optimization

Supported by global service and technical teams

🌍 Applications Across Industries

Fiber laser cutting is now being used in:

Sheet metal fabrication

HVAC duct manufacturing

Electrical cabinets and enclosures

Elevator and escalator parts

Architectural and decorative metalwork

Its adaptability and efficiency make it indispensable in modern metalworking.

🚀 The Future of Metal Fabrication

The shift toward fiber laser technology is not just a trend—it’s the new standard. As industries demand faster turnaround, tighter tolerances, and lower costs, fiber lasers are proving to be the most effective solution. With ongoing innovation and automation integration, companies like Gecnclaser are driving the next wave of industrial transformation.

Ready to Upgrade Your Fabrication Process?

Explore Gecnclaser’s full range of fiber laser machines and take your business to the next level.