Automation

For sheet coils, front to end automation is made possible from decoiling, leveling, feeding, cutting, unloading, bending, welding and finished product stacking. The stereo pallet racks can make full use of space while storing sheets. In doing so, such centralized storage needs less footprint.

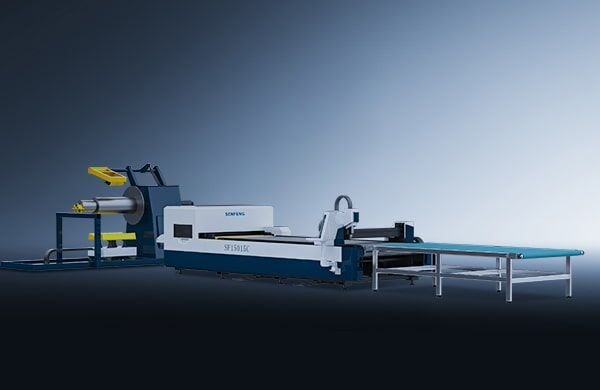

Coil Laser Cutting Machine For 0.6-1.2mm Steel

1.5 [kW] Laser power

3000*1500 [mm] Working area

0.6-1.2 [mm] Thickness of sheet coil

10 [T] Max weight of sheet coil

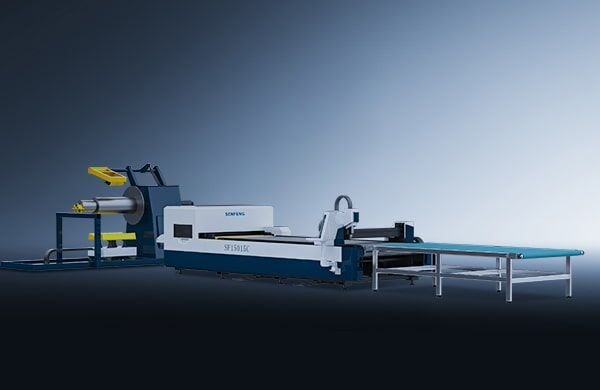

Coil Laser Cutting Machine For 0.6-3mm Steel

1.5-6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

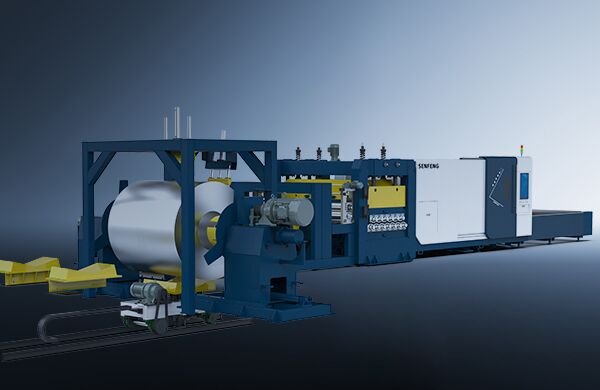

Flexible Metal Processing line TOP Series

3000 [mm] Max feeding length

1500 [mm] Max width of sheet coil

3 [mm] Max thickness of coiled sheet

10 [T] Max weight of sheet coil

1500 [mm] Max width of sheet coil

3 [mm] Max thickness of coiled sheet

10 [T] Max weight of sheet coil

Coil Laser Blanking Line For 0.6-2mm Steel

3-6 [kW] Laser power

4000*1500 [mm] Max working area

0.6-2 [mm] Thickness of sheet coil

10 [T] Max weight of sheet coil

Coil Laser Blanking Line For 8-14mm Steel

6 [kW] Laser power

4000*2000 [mm] Working area

8-14 [mm] Thickness of coiled sheet

20 [T] Max weight of sheet coil

4000*2000 [mm] Working area

8-14 [mm] Thickness of coiled sheet

20 [T] Max weight of sheet coil

Coil Laser Cutting Machine For 0.6-3mm Aluminum

6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

Laser Sheet Cutter with Loading and Unloading System

8 [layers] Stereo pallet racks

3000 [kg] Carrying capacity of each layer

3000*1500 [mm] Sheet size

10 [m/min] Warehouse-in/out speed