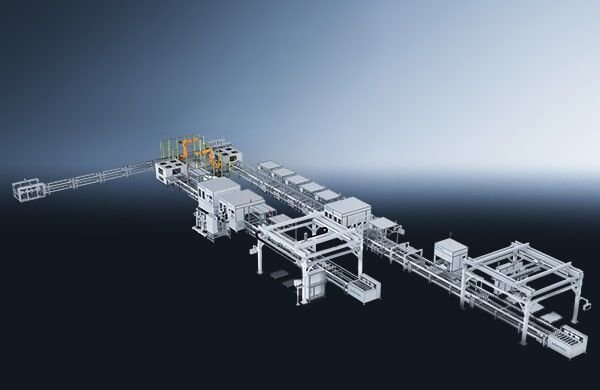

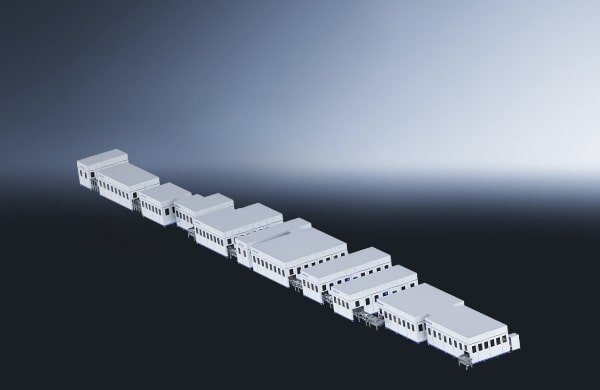

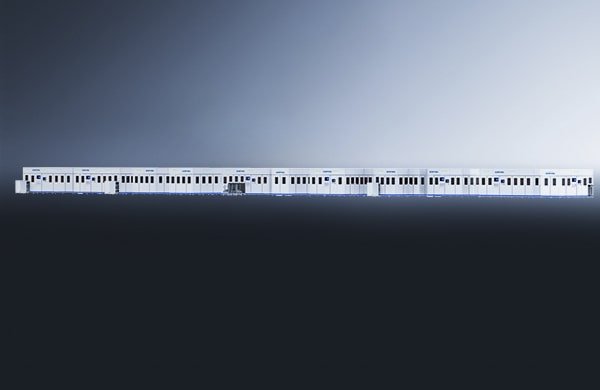

New Energy Battery Cell Assembly Line

This battery cell assembly line is modular-based and compact in structure. Due to its intelligent management, it is totally traceable. Combined with MES management system, the entire line is always under monitoring to keep all constituent devices stable. Key components are sourced from top brands, enhancing the line’s stability, compatibility, extension and safety.

Equipment Capacity: 12~24 PPM

Overall Line Yield: ≥99%

Overall Line Utilization Rate: ≥98%

Competitive Strengths

- Assembly automation

* Full automation runs through the entire line thanks to its advanced sensing technology, precision mechanical structure, intelligent control system and technical parameters that are under MES full-closed loop control.

* Each workstation is independently controlled, with AGV interfacing with intelligent warehousing for automatic transport.

- User-based customization

* Equipped with tailor-made control system that can monitor production data in real time, optimize process flows, improve production efficiency and product quality.

* Provide personalized solutions based on specific needs, and ensure its seamless integration with customer’s production system.

- Strict quality control

* Carry out all-sided intelligent quality inspections, incl. appearance, performance and safety tests.

* Build data management system for digital control and easy tracking of each module’s production history and quality.

* Raise production efficiency and reduce human factors’ impact on product quality through automated equipment and intelligent management systems.

- User-friendly operation

* It is ergonomically designed to minimize manual operation and reduce labor intensity.

* Control system interface is simple and intuitive, making it easy to operate and maintain.

* Main display screen centrally shows production data for easy monitoring and management.

Mechanical Benefits

- Reasonable design

* The entire line is designed in accordance with relevant design and technological standards to support diversified demands.

* Efficient logistics methods are employed to ensure fast moving and switch of battery cells at each workstation.

* Advanced control technologies and all-round dust removal measures are adopted to keep battery cell assembly clean.

* Compatible with various battery cells (fast switch among them), and allow for customization based on customer needs.

- Technological process

Preheating→hot pressing→insulation testing→tab cutting→ultrasonic welding→adapter laser welding→welding inspection→cell assembly→coating-heating→cell inserting can→laser pre-welding→laser full welding→weld inspection→insulation testing→leakage testing

- Key spare parts at high quality

* Key components are made of special materials to make sure of their high quality.

* Tooling fixtures are reasonably designed to keep battery cells stable and safe during assembly.

* Laser welding machine with annular laser spot can ensure welding quality and make battery cells much safer.

* Precision moving device, thanks to high degree of automation and intelligent control, can enable accurate positioning and fast assembly of battery cells.

- Safety measures

* Come with safety switch and safety light curtain to prohibit the opening of safety door in operation, and shut down automatically while opening.

* Safety devices such as fuse protector and temperature sensor are installed in battery system to promptly cut off power in case of battery cell abnormality.

Control System Benefits

- Collect messages quickly

* It can collect key parameters from each process in real time by using advanced sensor, RFID and wireless communication technology.

* The messages above are transmitted to central control unit for rapid treatment and analysis.

* These messages will be intelligently monitored and analyzed to make sure of safety.

* It also records production process and key parameters, in order to trace back quality and issues.

- Take integrated control

* Its full automation is benefit from advanced automation equipment and technology, which can get efficiency gains and reduce errors and safety hazards caused by manual intervention.

* The system collects, delves into and analyzes big data from production, then, optimizes production processes and parameters based on data analysis results.

* The control system is compatible with various products and allows for further upgrades as need.

- Real-time display

* The system monitors and shows welding parameters, visual inspection, testing parameters, pressure and displacement in real time at work.

* It works with MES system, laser coding and RFID technology to track data for each product.

* At work, machine status is visualized and message interaction is made possible, so, operators are able to check its running state in real time.

Get In touch

Technical Parameters

| Main Parameters | Model |

| New Energy Battery Cell Assembly Line | |

| Total capacity | 12~24PPM |

| Final excellent rate | ≥99% |

| Machine utilization rate | ≥98% |

| Power Supply | Three-phase 380V, 50Hz/60Hz |

Get In touch

1. Intelligent extension

* Due to its modular-based structure, users’ personalized demands and other optional functions are also available.

* New materials and processes are permitted to use to make the production highly efficient. New welding technology also helps to get efficiency gains and high quality.

* Low-energy and low-emission devices or processes can also be utilized to minimize effect on environment and make resources recycling.

Get In touch

What kind of company is Gecnclaser ?

Does Gecnclaser accept customization?

Yes, users can apply for customization of machine color, logo, overall dimensions and main configurations according to their preferences and actual needs, such as, core components like laser generator, cutting head, control system, water chiller, speed reducer and electrical system of different brands and functions. We will provide personalized solutions for global users within feasible limits.

What modes of payment are available?

At present, Gecnclaser supports T/T, L/C, Alipay, etc. We respect the customer’s right to choose their most fitting payment mode and will do our best to keep their funds safe.

Does Gecnclaser provide technical support and after-sales service?

Yes, Gecnclaser offers pre-sales, in-sales and after-sales services to global users both online and offline.

On one hand, hundreds of overseas customer service agents are available online 24/7 to answer various inquiries, including product consultation, customized solutions, complaints, etc., and we have established an online knowledge center providing a one-stop knowledge database.

On the other hand, sales engineers, technical engineers and after-sales engineers frequently visit customer sites for face-to-face communication to settle user’s troubles back at home.

More importantly, we also provide free online and offline operational training, such as theoretical & practical training, common fault self-diagnosis training and quick repair guidance for difficult faults, enabling all users even beginners to get started quickly.

How can I get a quote or more information?

Firstly, machine pricing depends on its laser power and technical configurations, so please leave a message with your specific requirements. Then, a sales engineer will recommend a suitable model for you before providing a quote.

Secondly, if you want to learn more about our company or products, you can browse this website in detail, contact us through WeChat official account, Facebook, YouTube, Twitter, Instagram, WhatsApp, etc., or request our internal promotional materials from a sales engineer, visit our overseas service centers nearby directly.