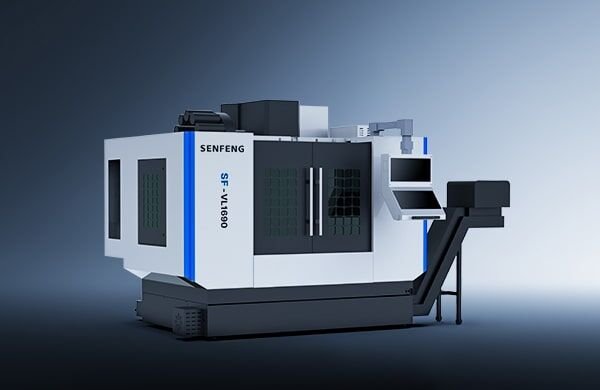

High-Precision Vertical Machining Center CNC Milling Machine

Vertical machining center, developing from CNC milling machine, can carry out vertical milling, drilling, boring, expanding, tapping and other procedures after one-time clamping of workpiece. It is used by SENFENG to set the global quality milling trend. With it, users can respond to the market instantly.

1000*550-1600*800 [mm] Worktable size

6000/8000 [r/min] Max speed of spindle

24 [cutter] Tool magazine capacity

2.5 [s] Tool changing time

Competitive Strengths

Performance Benefits

This roll lathe is ideally fit to handle large rolls like special steel, which will help users to lower total costs and raise work efficiency.

- High in working ability

* The machine can roll into holes and carry out turning on excircle, roll neck and other similar spare parts.

* It can deal with cast steel, forged steel, alloy steel, chilled cast iron, nodular cast iron, tungsten carbide roller ring , large special steel and so on to realize fast processing at high precision.

- Work at high quality

* Take accurate control of all axes’ speed, so that it offers accurate work and quality products.

* Control multiple axes in the meantime to execute more meticulous and complex tasks

* Outfitted with sensors and controllers to monitor and adjust work process, in doing so, its finished products can always reach specifications and accuracy required.

- Safe operation

Its auto-protecting function avoids unforeseen accidents.

Mechanical Benefits

- Horizontal structure

The machine is designed as horizontal, with relatively small footprint.

- High-precision spindle bearing

We adopt Japanese NSK high-precision spindle bearing and German Kluber NBU15 high-grade lubricating grease, therefore, its precision and rigidity are up to standards.

- CNC vertical turret tool holder

It requires much less tool-to-tool time and non-productive duration. Before delivery, the turret has gone through running tests to keep itself stable and long-life.

- Cast-solid lathe frame

4 guide rails are used to maintain absolute stability and precision, which also ensure that the pallet can run smoothly in the entire work area. In this way, cuttings may be removed through wide exit, with no effect on guide rail precision.

- Other key components

* φ630 four-claw chuck is used for fastening workpieces and preventing any movement at work.

* Plastering mobile sliding plate is featured by small frictional coefficient and long service life, resulting in high moving accuracy and long lifespan.

* Tailstock is equipped with live spindle and axially telescopic socket. Its spindle reserves Morse 6 tapered bore.

* To keep the machine’s precision, stability and working life, we invest more on its core components from world famous brands, such as German Schneider electrical elements and Japanese NSK lead screw bearing and tailstock bearing.

Control System Benefits

Its intelligent CNC system special for roll lathe and based on GSK-Link industrial Ethernet bus, comes standard with bus-based servo drive unit and motor to enable widespread use and user-friendly operation.

- Tool life management

Show tool’s use condition in real time and remind users to change tools in time

- Real-time monitoring of servo state

Visually reveal the real state of all components, so as to prevent possible accident

- Emergency stop alarm

The machine stops instantly as long as emergency stop button is pressed down in emergency

Get In touch

Technical Parameters

| Main Parameters | Model | ||||||

| SF-VL855 | SF-VL1160 | SF-VL1160P | SF-VL1370 | SF-VL1580 | SF-VL1690 | ||

| Worktable | Dimensions (mm) | 1000*550 | 1200*600 | 1200*600 | 1400*700 | 1600*800 | 1600*800 |

| Max Load (kg) | 500 | 800 | 800 | 800 | 1500 | 1500 | |

| T-slot Size (mm) | 5-18-90 | 5-18-100 | 5-18-100 | 5-18-130 | 7-22-110 | 7-22-110 | |

| Processing Range | 3-axis Travel (mm) | 800*550*550 | 1100*600*600 | 1100*600*600 | 1300*700*750 | 1500*800*700 | 1600*900*700 |

| Distance from Spindle Nose to Table Surface (mm) | 120-670 | 120-720 | 120-720 | 120-870 | 160-860 | 150-850 | |

| Distance from Spindle Center to Z-axis Guideway Surface (mm) | 590 | 650 | 650 | 722 | 855 | 910 | |

| Spindle | Taper Hole (7:24) | BT40 Φ150 | BT40 Φ150 | BT40 Φ150 | BT40 Φ150 | BT50 Φ155 | BT50 Φ190 |

| Speed Range (r/min) | 8000 | 8000 | 8000 | 8000 | 6000 | 6000 | |

| Feed | 3-axis Rapid Speed (m/min) | 32/32/24 | 24/24/18 | 36/36/24 | 24/24/18 | 24/24/24 | 20/20/12 |

| Feed Speed (mm/min) | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | |

| Disc Tool hanger | Capacity | 24T | 24T | 24T | 24T | 24T | 24T |

| Tool Changing Time (s) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Positioning Accuracy | X/Y/Z-axis Positioning/Repositioning Accuracy (mm) | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 |

Get In touch

Get In touch

What is CNC Milling Machine?

It is an equipment that uses digital information control to carry out milling. It has characteristics of high precision, high efficiency and high automation, and develops into an indispensable equipment in modern manufacturing industry.

What are the main advantages of CNC Milling Machine?

Compared to other common machine tools, it is featured by:

* High processing accuracy with stable quality.

* Capable of multi-coordinate linkage, allowing for the cutting of complex-shaped parts.

* When changing spare parts, only CNC program needs to be modified, saving make-ready time for production.

* The machine tool itself has high precision and rigidity, resulting in high productivity (typically 3-5 times that of others).

* High degree of automation, which can reduce labor intensity.

* Higher quality requirements for operators and even higher technical requirements for maintenance staff.

What are main applications of CNC Milling Machine?

Currently, it has been widely used in machinery manufacturing industry and can deal with shaft, disc and sleeve-shaped parts. For example, CNC Milling Machines is extensively used for processing components like engine blocks, cylinder heads and crankshafts in automotive manufacturing industry. As for aerospace field where spare parts are under high precision requirements, CNC machine tool can also meet the demands for high-precision machining.

What is the warranty period of CNC Milling Machine?

The complete machine is under 1-year warranty. Its main accessories and consumables will be replaced depending on their specific service life. We also provide original accessories for global users, with quotes available within 24h and delivery within 3-7 working days. The change of these accessories will be given priority to our nearby subsidiaries or local service centers.