Industry Overview

Elevator industry spans the globe, which continues to grow with the rapid development of urbanization. According to incomplete statistics from a professional organization, the global elevator market is expected to reach a scale of $115 billion by 2025. From a technological development perspective, the elevator industry is continuously evolving towards intelligence, energy efficiency and environmental protection. Smart elevator is set to become the future, offering advantages such as safety, comfort, efficiency, energy saving and environmental friendliness.

⇲ Passenger elevator

⇲ Freight elevator

⇲ Home elevator

⇲ Escalator

⇲ Scenic elevator

⇲ Car elevator

Metal Fabrication Processes

In China, elevator is classified as special equipment, and the country has strict requirements for its manufacturing, installation and use to ensure safety and reliability, thereby protecting the personal and property safety of users. Various components, accessories and panels of elevator require various techniques such as cutting, bending and stamping. In recent years, laser technology has been widely applied in sheet metal processing of elevator.

- Laser Cutting

- Hole stamping

- Bend into shape

- Laser welding

GENCLASER’s Advantages

As demands for elevator continue to increase, the safety, space constraints and aesthetic requirements have become challenges that must be addressed during elevator manufacturing. Fortunately, SENFENG, with cutting-edge laser technologies, can provide well-targeted solutions for elevator manufacturers.

1)Offer Complete Product Line

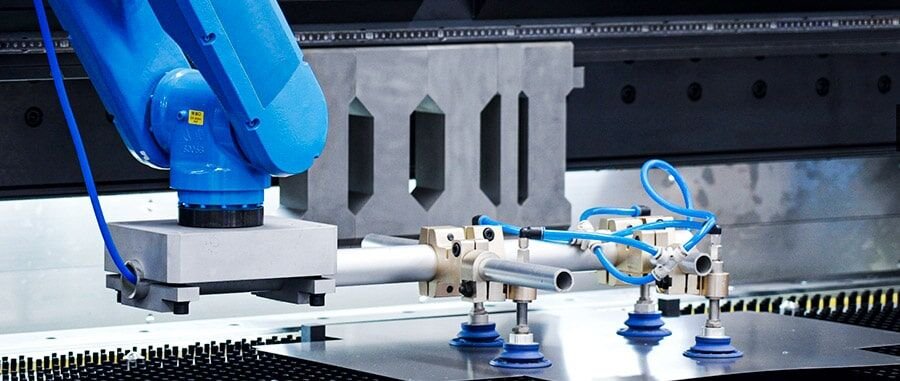

For safety reasons, elevator components (elevator car, door and foot plate) are primarily made of metallic materials such as painted and stainless steel plates. All these metals fall within the processing range of SENFENG products. We have developed sheet, tube laser cutting machines, flexible panel benders and various handheld/robot-assisted laser welding machines. All are capable of handling with most metallic materials on the market, meeting the diverse needs of elevator users.

2)Make Elevator More Aesthetically Pleasing

The manufacturing of elevator often involves stainless steel plates and film materials, which require high level of surface finish. Using SENFENG’s laser cutting machines will bring about smooth cutting lines with high surface quality, eliminate mold wear and allow for the finer and smaller sharp corners. This helps to prevent workpiece deformation, improve elevator quality and make elevator manufacturers more competitive.

3)High Flexibility of Elevator Production

With the rising of people’s aesthetic sense, the variety and shape of elevator have increased, along with more complex contours that ordinary machines can’t achieve. SENFENG’s laser cutting machines are highly automated and intelligent, capable of handling various irregular workpieces, as thus, reduce labor intensity for operators and streamline manufacturing workflows.

4)Keep Elevator Safe

Traditional reinforcement ribs for elevator car, car top and bottom are typically connected by using adhesive methods. While this approach is cost-effective, it has poor durability and low strength, leading to detachment over time. So it is only suitable for ordinary elevators. However, future high-rise elevators will play a crucial role as lifelines in fire emergencies. In this way, such traditional processes must be improved. SENFENG’s laser welding offers deep penetration, minimal deformation, high strength and a small heat-affected zone, helping to maintain the original performance of raw materials. In some cases, its welding strength even exceeds that of the base material, and the welds are solid and nice-looking, meeting the requirements for high-rise elevators at present and in the future.

Relevant Customer Case

HSD is a Chinese metalworking company that mainly cuts medium-thick plates. Previously, they relied on manual beveling, which involved many processes, high labor input but low efficiency. After using SENFENG’s Ultra-large Beveling Laser Metal Cutter SF26040TX Series, it is 75% faster than before because of one-step forming of ±45° bevel. Besides, it is easy to cut plates in batch, making for a significant increase in order volume.

Time of purchase: May 2009-Oct. 2024

⇲ Specific model:

1313G Series 1300*1300mm Fiber Laser Sheet Cutter

1503CH Series Coil Laser Cutting Machine For 0.6-3mm Steel

TOP Series Flexible Metal Processing Line