Industry Overview

Medical device refers to instrument, equipment, tool, IVD reagent, calibrant and other similar or related items that are used directly or indirectly on human body. With the accelerated global aging, the trend of diseases affecting younger individuals, and the continuous increase in per capita healthcare spending, China’s medical device market has reached a trillion yuan scale, with immense market potentials. In the context of its rapid iteration, advanced intelligent manufacturing technologies such as “laser+” are deeply integrating with various manufacturing stages of medical device, which drives this industry towards greater efficiency, intelligence and smart development.

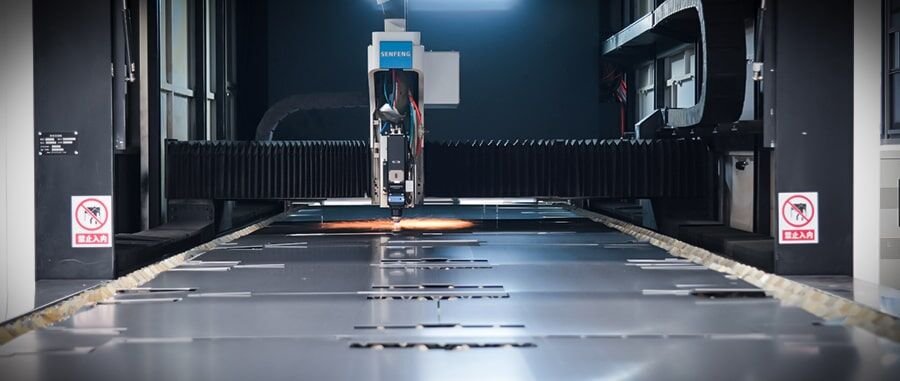

Metal Fabrication Processes

Regarding human life safety, medical device manufacturers typically impose strict requirements on the production of medical device, necessitating high-quality and high-stability precision processing. However, traditional methods still have many shortcomings in terms of precision and safety, which makes the replacement by high-precision laser machines an inevitable trend in its development.

- Laser drilling

- Laser cutting

- Laser micro-welding

Advantages

For medical device, precision directly relates to its degree of compliance. Only by abiding by precision baseline does speeding up production. GECNCLASER’s machines are equipped with hi-end intelligent CNC systems for control, significantly surpassing the precision of manual operations by skilled workers.

01 Accelerate Research and Development

Generally, the functional upgrade of surgical devices such as operating table and shadowless lamp heavily relies on the feasibility of actual production. If production fails, even the most ideal design plans will remain on paper. However, medical device manufacturers may introduce GECNCLASER’s laser technology into the early R&D stage. By inputting design drawing into our CNC system, precision will be high enough with an error of 0.1mm. In this way, new design ideas will be verified on the basis of physical prototypes.

02 Achieve Precision Manufacturing

When cutting complex-shaped medical devices (such as heart stent, thrombectomy stent, catheter, etc.), challenges like burr, multi-axis linkage and process control often arise, affecting the fine structure of these devices. GECNCLASER’s laser energy precise-control technology can regulate laser beam, while coaxial gas nozzle is used to remove waste and get simple, fast and pollution-free production. Moreover, advanced lightning-fast and mirror-like surface cutting techniques are able to eliminate the excess heat and burr, so that cutting section becomes really neat.

03 Offer High-Quality Welding

While welding reusable medical device, the stability of weld spot and the density of weld seams are crucial. GECNCLASER can provide a complete set of equipment and solutions for medical device welding, ranging from manual to fully automatic welding, from spot welding to complex paths. Our welding solutions can ensure that weld spot, weld seam and the gap between airtight sealing are far less than 1 mm, with excellent surface quality that requires no after-treatment.

04 Make Product Delivery Faster

In addition to machine quality, customers also place great importance on delivery speed. GECNCLASER is in possession of various fully-automatic laser cutting machines, press brakes and robot-assisted laser welding machine. Metal processing that previously required cumbersome multi-process steps, such as the production of paunch flusher shell, which relied on shearing, punching and grinding, and the underpan production of operating table that is made of steel pipe requiring punching and polishing, can now be completed in one go by only one laser production line, significantly reducing production time and accelerating product delivery speed.

Relevant Customer Case

The customer is a national hi-tech enterprise established in 2006, specializing in the R&D, production and sales of medical device such as surgical shadowless lamp, operating table and survey aspirator. It spreads over domestic sale, export and government procurement.

In Oct. 2024, it purchased a single-chuck laser tube cutting machine and a handheld laser welding machine from GECNCLASER. With that, the company responds more quickly to market demands and achieves high-mix, small-volume production. According to the customer’s representative, “using the previous machines, 100 medical devices would take 7 days to complete, but now it can be done in 1 day. This allows for our production of over 30,000 medical devices (sets) annually.”

⇲ Time of purchase: Oct. 2024

⇲ Specific model:

SF6008T Series Single-chuck Tube Laser for Small Tubes

HWM Series Handheld Fiber Laser Welding Machine